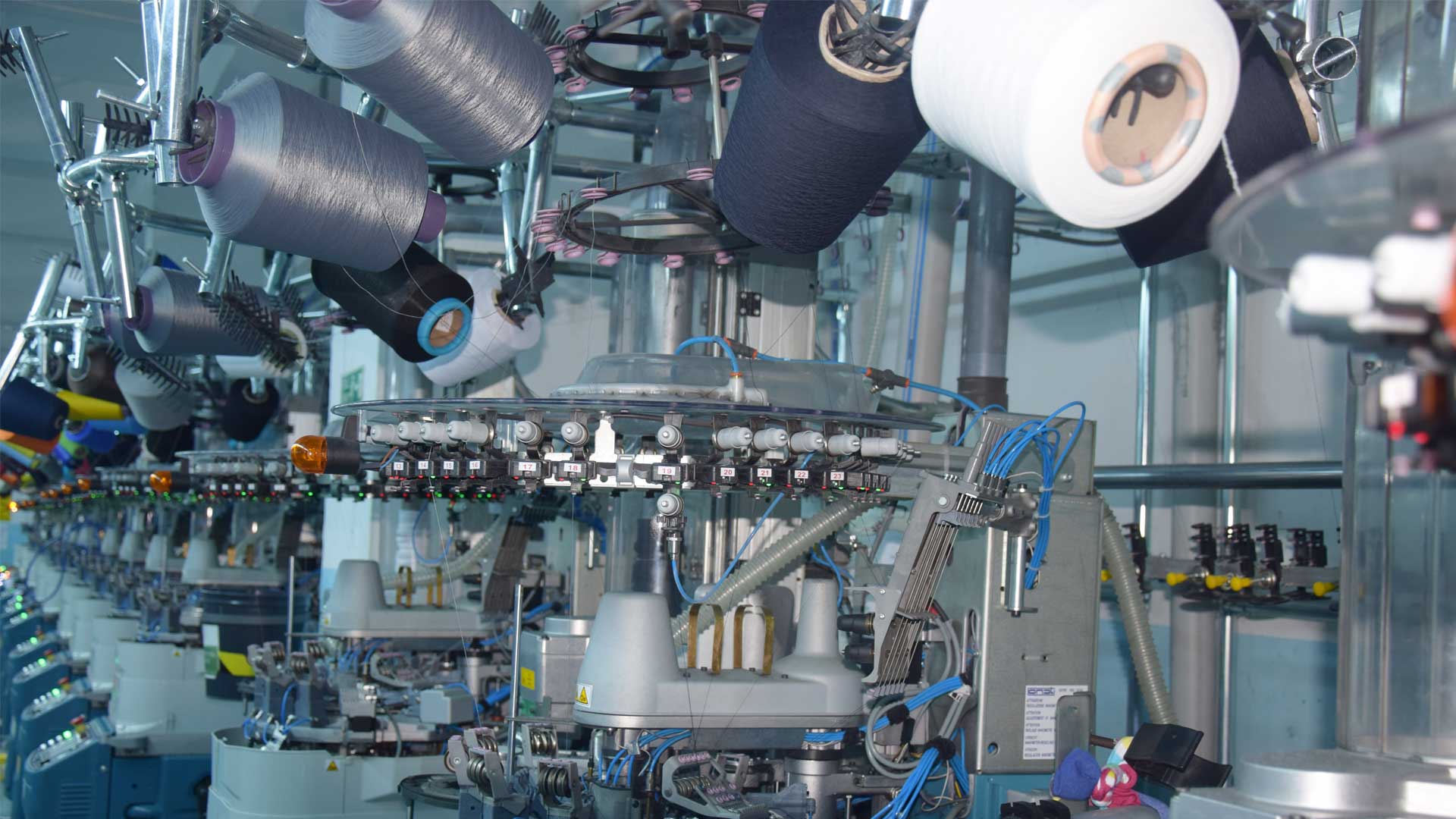

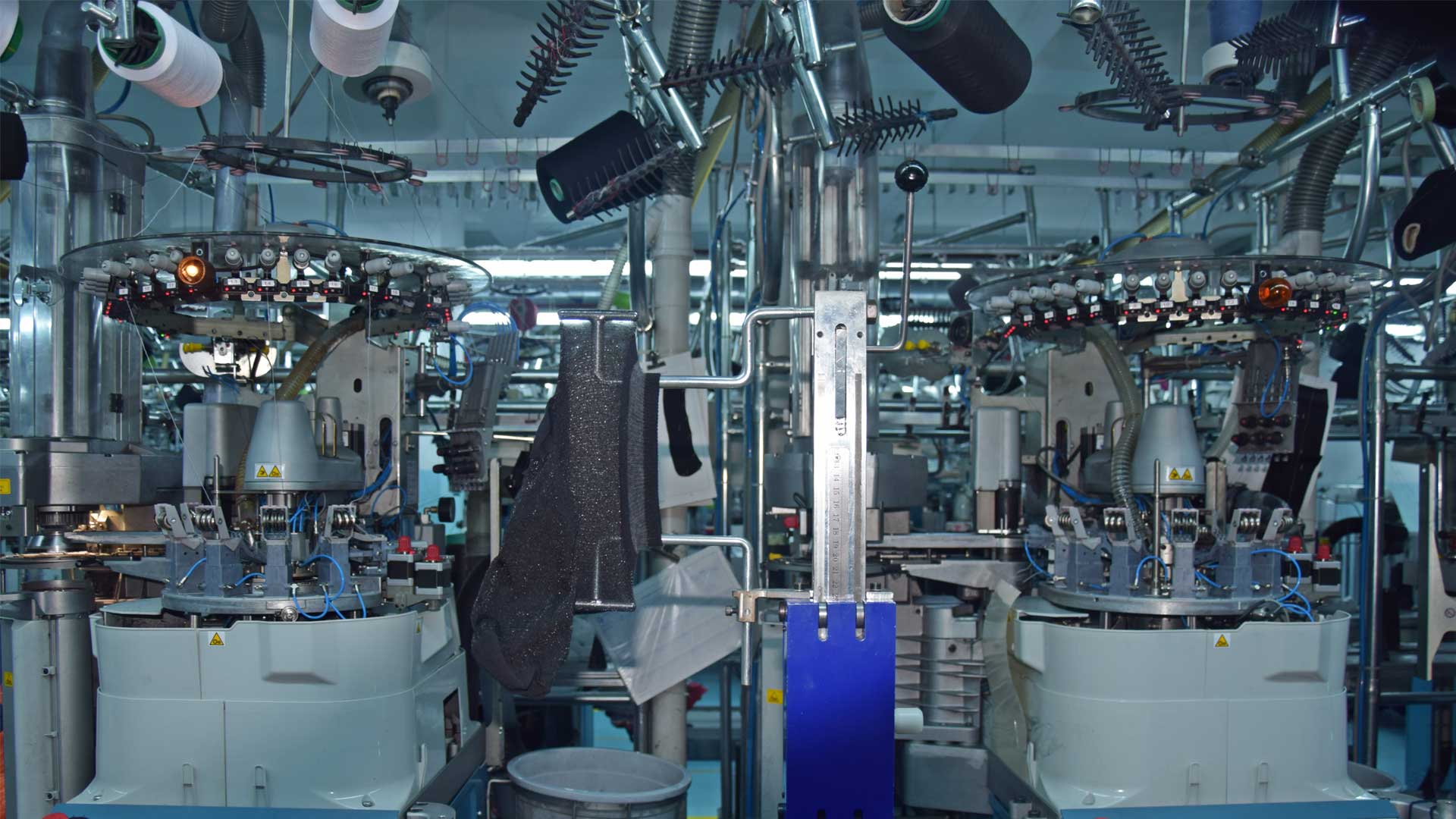

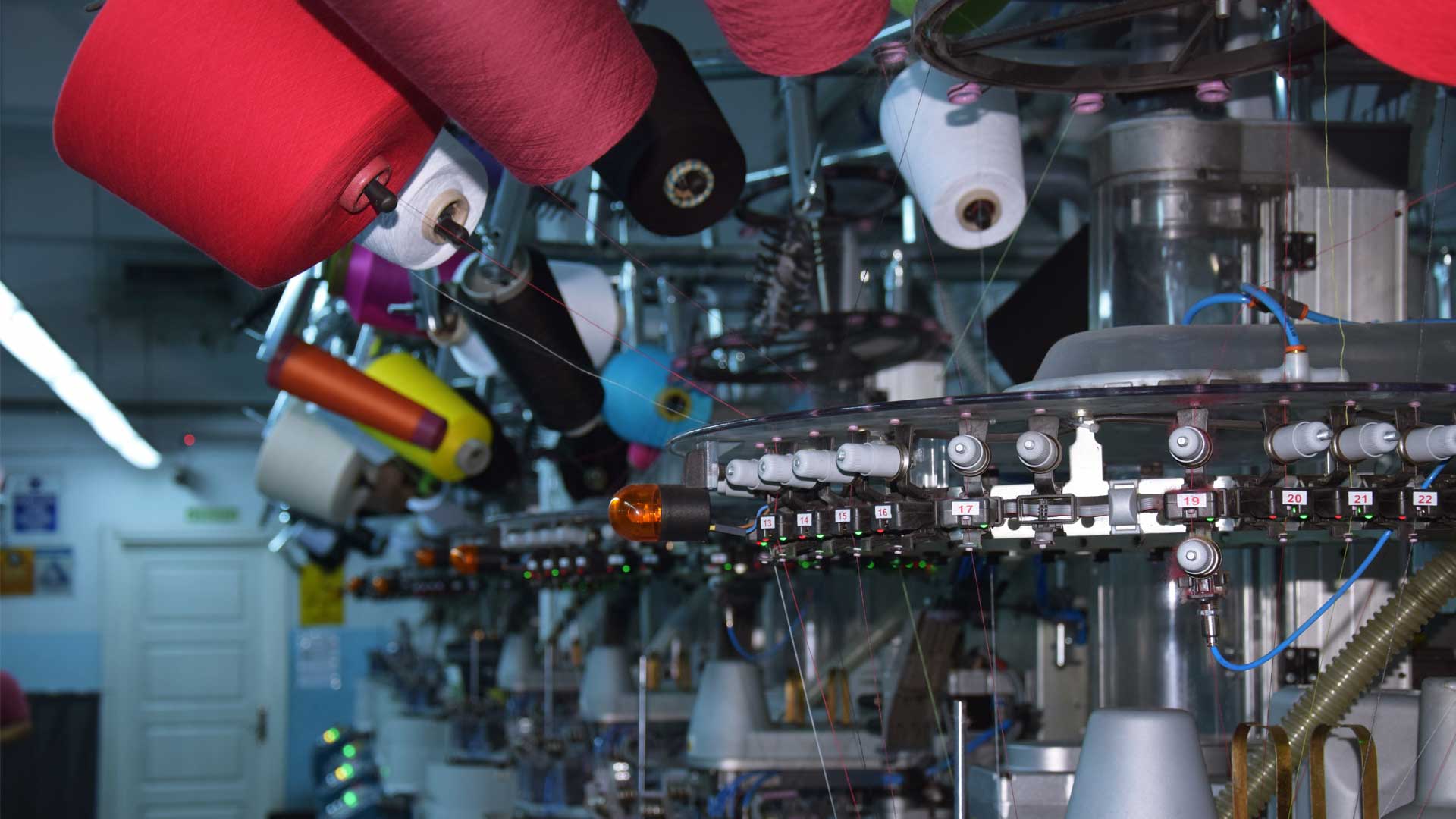

KNITTING

Gencler Socks has largest capacity production factories in Europe with 90 single cylinder Lonati knitting machines in total with a wide range of needle groups from 144 needle to 200 needles.

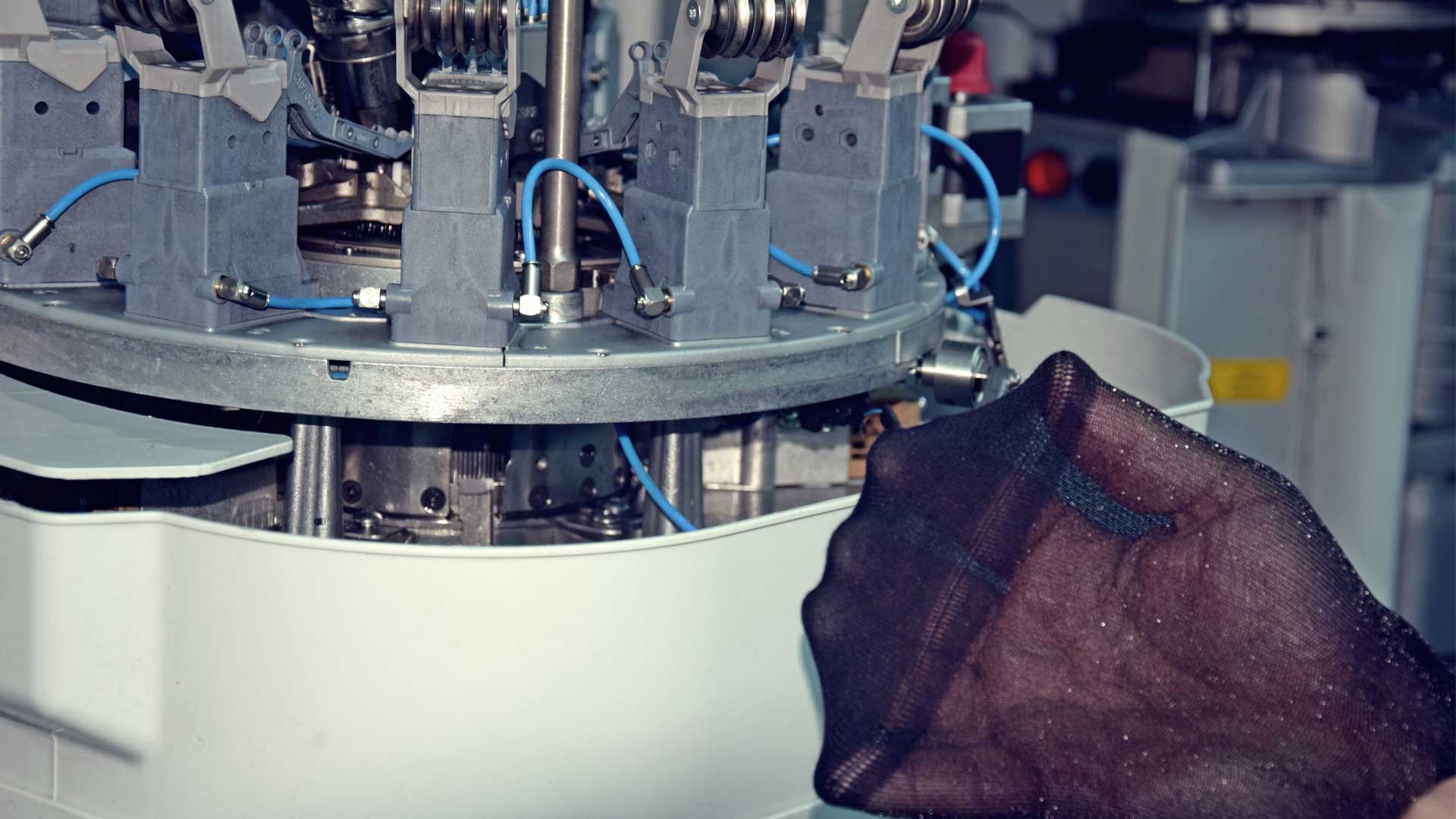

TOE CLOSING

Gencler Socks has 3 Hand Linking toe closing and 4 rosso toe machines.

BOARDING & PACKING

Gencler Socks has 3 steam boarding machines. We have gained a lot of experience with optimum temperature, time and steam pressure settings

METAL DETECTION

Gencler Socks has metal detectors. The goods are transferred from the packaging department and are passed through metal detectors to confirm there are no metal parts in the product.

Gencler Socks applies a strict broken needle policy in every process and ensures all workers are aware of this policy.

QUALITY CONTROL

Various quality control procedures are followed for all manufacturing operations by the ‘Quality Control Teams’ in all the production operations to provide high quality products. Thanks to these quality controls, Gencler Socks can achieve all of the required product safety standards and in addition continuously improve its product quality.

In addition to all of these control systems, all the finished goods receive a further final inspection prior to despatch.