Gencler Socks is located in Esenyurt and the company that has been serving in the Turkish socks industry over 20 years. With its 6.000 m2 closed area and modern facility, it provides quality products and services to its customers.

Our firm produces 10.000.000 (ten million) pairs of men, women and teenages with years of investments. We export 100% of our production to European markets.

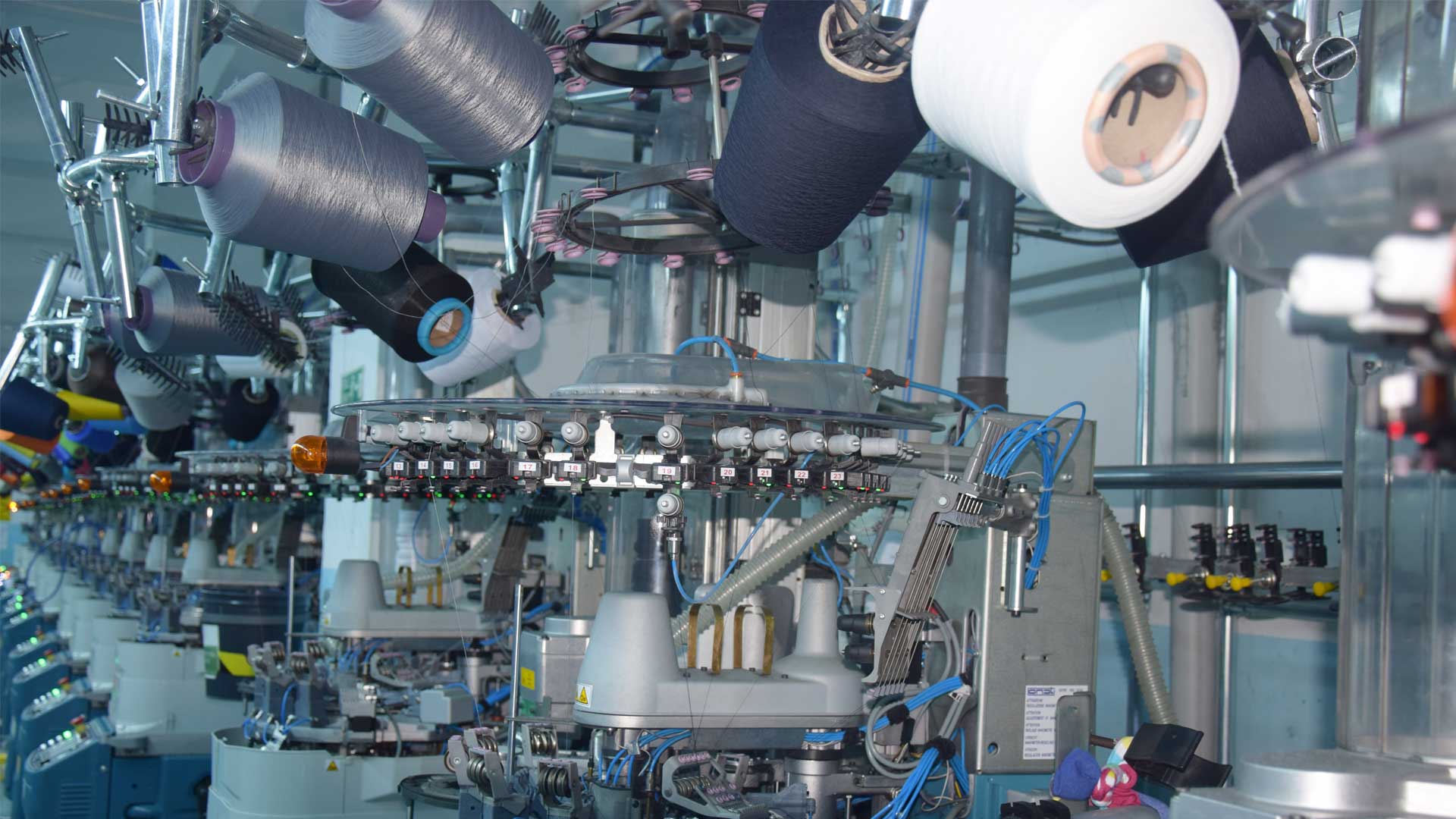

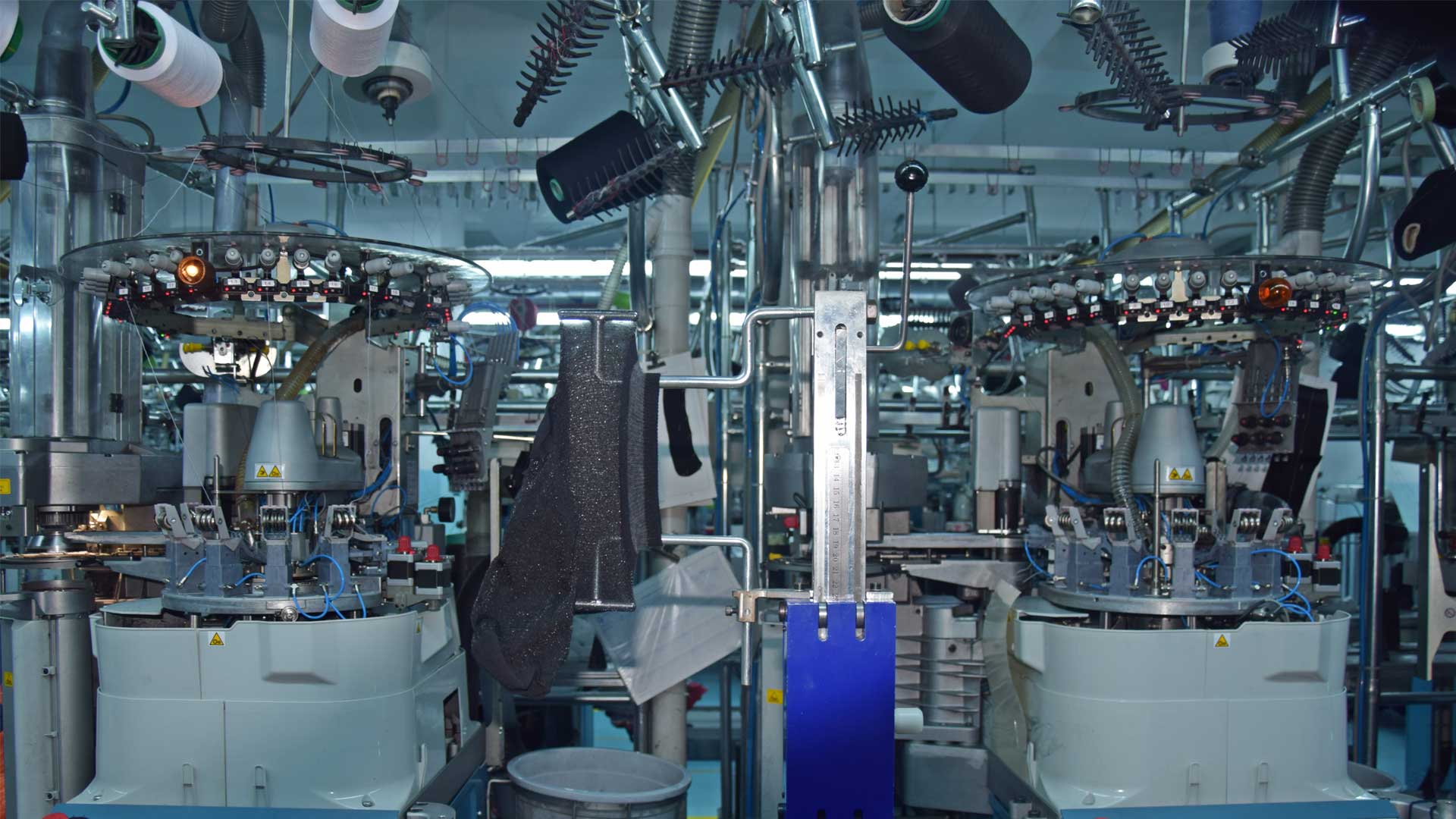

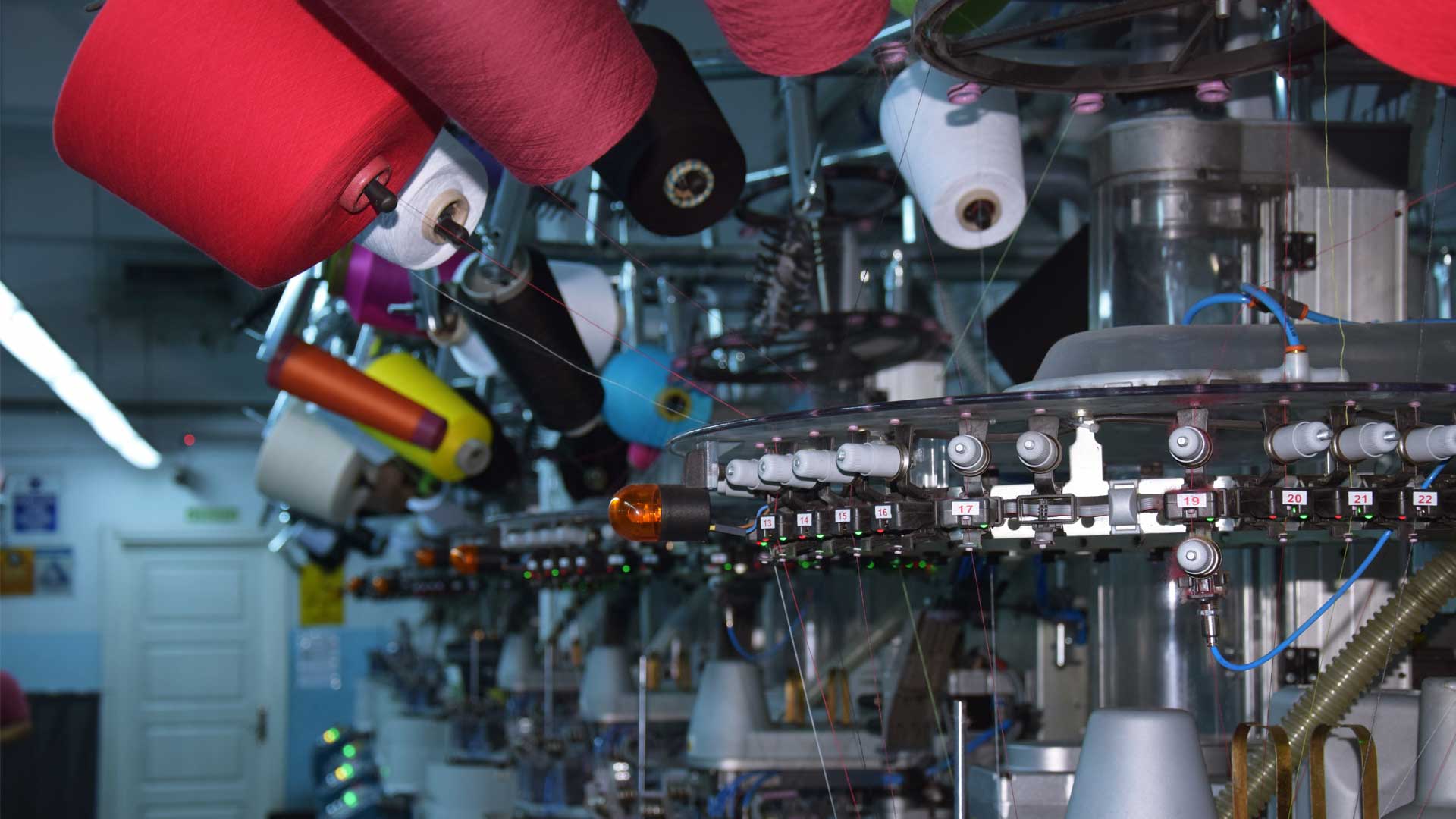

Our company has 90 machines Lonatti machine park with the capacity to provide customers with products and services.

Our boarding and packing facility uses Heliott steam ironing machines, which have the most recent technology in this field. We can form up to 720.000 pairs socks per month in our facility

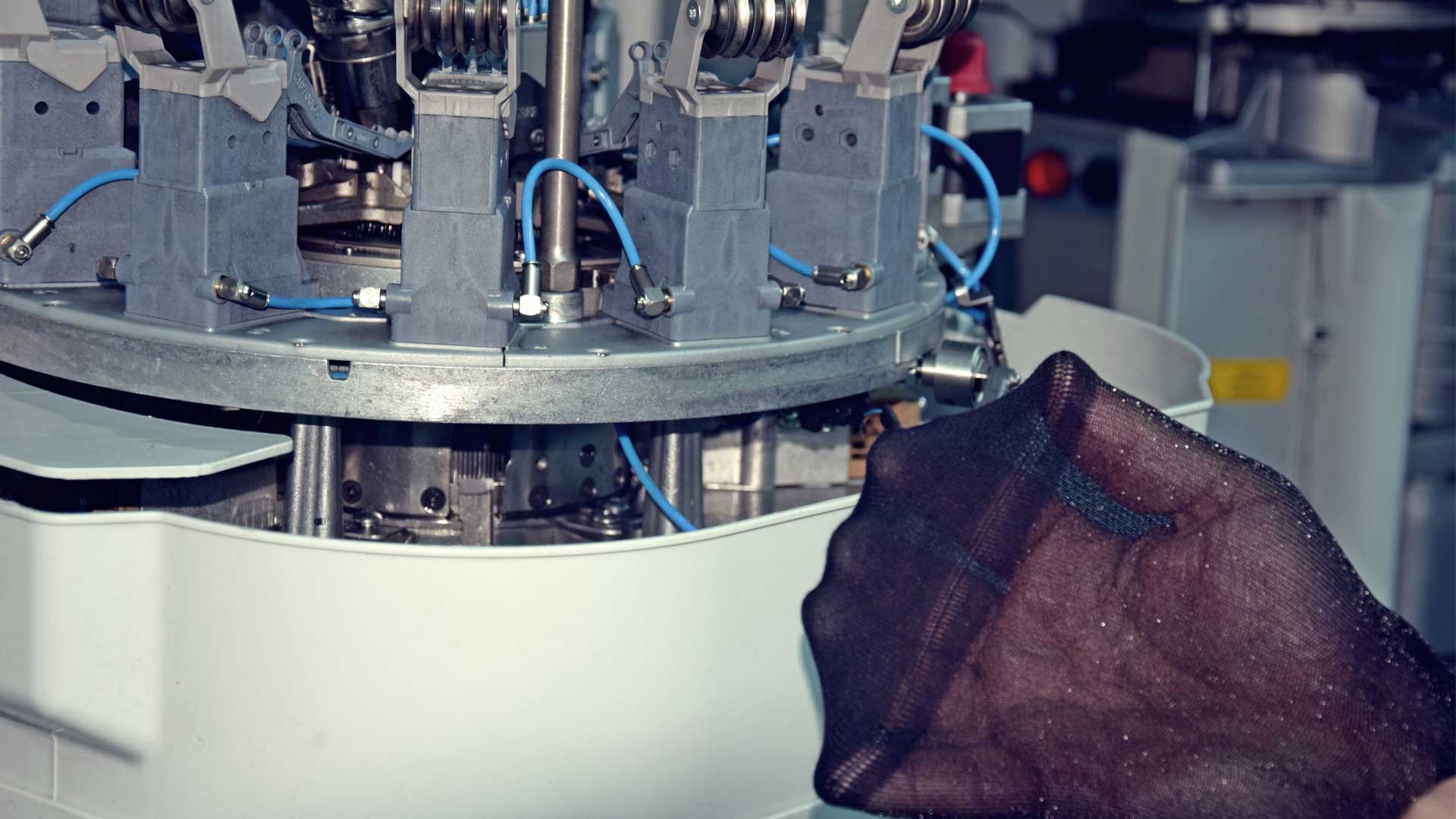

The toe-closing department has Rosso and Conti toe seam machines as well as having hosiery machines equipped with automatic LinToe and classic toe closing capabilities.

We have a large and elegantly designed showroom for our customers, where we proudly display our wide range of produced socks.

With our work force of more than 90 employees, we are eager to provide our customers with a wide range of production and side facilities.

WE ARE SERIOUS PEOPLE

Responsibility

WE ARE PASSIONATE

Creativity

WE ARE DETERMINED

Quality

Our Quality Certificates

• Our company is completely free of metal.

• In all the process from raw material to finished product delivery entrance was taken precautions to any matter that may pose a risk to human health.

• Employees hired since the first introduction of metal is supported by continuous training and are informed.

• Any device that is required for metal control, machinery and equipment, and we’re doing their maintenance regularly.

• We renew ourselves continuously monitors developments and changes related to this topic.

• Our company is in the understanding of any subject as well as being a pioneer in this regard and the sample firms

Our Quality Certificates

• Our company is completely free of metal.

• In all the process from raw material to finished product delivery entrance was taken precautions to any matter that may pose a risk to human health.

• Employees hired since the first introduction of metal is supported by continuous training and are informed.

• Any device that is required for metal control, machinery and equipment, and we’re doing their maintenance regularly.

• We renew ourselves continuously monitors developments and changes related to this topic.

• Our company is in the understanding of any subject as well as being a pioneer in this regard and the sample firms

Sedex

Oeko-Tex

Global Organic